In the dynamic modern manufacturing industry, ensuring the integrity of machinery and the efficiency of products and machines is of paramount importance. Rubber sealing solutions are one of the most important factors in achieving this. Rubber seals have many uses, as they provide airtight/watertight barriers, which help prevent leaks. Selectlok, a company that offers innovative sealing solutions, has led the way in the advancement of technology. This article explores some of the most recent innovations in rubber sealing and their impact on modern production.

Rubber Sealing Is Important For Manufacturing

Rubber seals are crucial components used in many manufacturing processes to ensure the functionality and durability of machinery, products, and equipment. Seals are created in gaps, joints, and interfaces to stop liquids, dust, and gases from entering. This increases the performance, reliability, and lifespan of equipment by preventing wear.

Rubber Sealing: Benefits

- Leak Prevention: A rubber seal is an effective barrier that prevents leaks. It ensures fluids and other gases are contained within the systems. This is vital in industries including automotive, aerospace, and pharmaceuticals. A minor leak could cause serious problems.

- Protecting The environment: Rubber seals shield the environment by keeping impurities like dust and other particles out of delicate parts. It is of particular importance in outdoor or harsh environments.

- Vibration Dampening: rubber seals can also be used to dampen vibrations. They reduce noise and contribute to a smooth and quiet machine operation.

- Temperature Resistance: High-performance rubber seals have the ability to resist extreme temperatures. This makes them perfect for applications under extreme conditions.

Rubber Sealing Solutions Innovations

As manufacturing techniques become more complex, the need for innovative sealing solutions has increased. Selectlok is a leader in the rubber sealing industry, creating cutting-edge solutions to meet the demands of modern manufacturing.

Advanced Materials

Using advanced materials in rubber sealing is a significant innovation. Modern formulations for traditional rubber seals provide improved performance. In particular, silicone rubber sealings are well-known for their high-temperature resistance. They also offer excellent flexibility. This makes them ideal for applications at both low and high temperatures. Fluorocarbon sealing rubbers have exceptional chemical resistance. This makes them suitable for use even in harsh chemical environments.

Customization & Precision Engineering

Modern manufacturing is often reliant on seals that are custom-made for specific applications. Selectlok Rubber Sealing Solutions offer precision-engineered customized sealing solutions to meet unique industry requirements. Seals are available in various sizes, shapes, and materials. Additionally, they may be altered to fit and function exactly as intended. Customization includes multi-functional, multi-property seals. These seals combine chemical resistance, durability, and temperature resistance.

Durability, Longevity, And Durability Are Enhanced

Rubber sealing technologies have been developed to improve durability and longevity. A combination of modern manufacturing and material science has enabled seals with greater resistance to wear and tear. This is crucial in applications that are subject to seals to constant friction and movement. By increasing the durability of rubber sealings, manufacturers are able to reduce maintenance costs as well as downtime.

Smart Sealing Solutions

It is exciting to see the integration of intelligent technology into rubber sealing systems. Selectlok rubber-sealing solutions are exploring IoT and sensors to create seals with the ability to monitor and communicate their condition. These smart sealing solutions can detect wear and leakage in real time. They allow proactive maintenance to be performed, as well as reducing the chance of unexpected failures. This innovation fits into the broader Industry 4.0 concept, where technology is used in manufacturing to improve efficiency and enhance processes.

Innovative Rubber Sealing Solutions

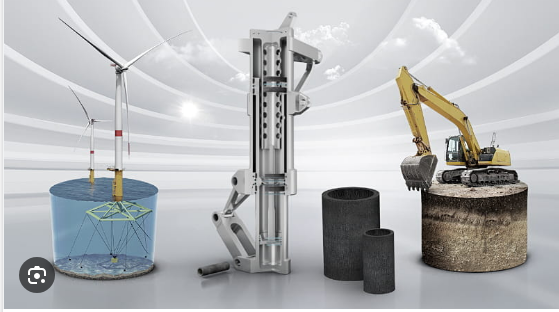

Rubber sealing technology has a broad range of applications. Some notable examples include:

Automotive Industry

Rubber seals are found in engines, transmissions, and other important automotive components. They prevent leaks and ensure optimal performance. The use of advanced rubber sealing technologies improves vehicle efficiency and reliability.

Aerospace Industry

The aerospace sector requires seals to be able to resist extreme temperatures, vibrations, and pressures. Innovative rubber sealing products provide the durability, performance, and safety required for aircraft components.

Conclusion

Innovative rubber seal solutions revolutionize modern manufacturing with their enhanced performance and durability. They also allow for customization. Selectlok Rubber Solutions, which offers products to meet the evolving requirements of many industries, is among the leading companies in this field. Demand for reliable and high-quality seals will continue to rise as manufacturing processes improve. By adopting innovations, manufacturers are able to ensure the integrity and effectiveness of their operations. They can also improve their productivity.