Introduction

Stainless steel has earned its reputation as the material of choice across industries as diverse as pharmaceuticals, food and beverage, energy, and water treatment. Its strength, cleanliness, and resistance to corrosion make it a cornerstone of modern infrastructure.

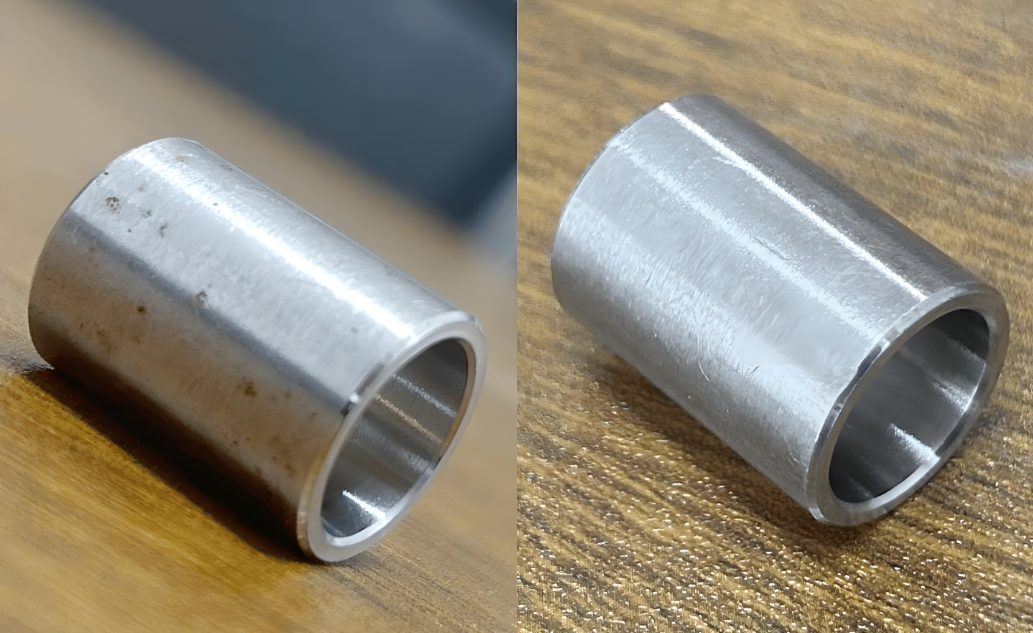

Yet stainless steel is not invulnerable. Welding, fabrication, and daily operation can leave behind free iron particles and surface impurities that compromise the metal’s natural protective layer. Left unchecked, this can lead to corrosion, rouge contamination, biofilm growth, and even equipment failure.

For this reason, the passivation of stainless steel is a critical step in maintaining system integrity and ensuring compliance with industry regulations. Far from being a niche process reserved for high-purity environments, passivation is a proactive, cost-effective strategy that benefits every sector.

What Is Stainless Steel Passivation?

At its core, stainless steel passivation is a chemical treatment designed to restore and enhance the passive layer—a thin but robust film of chromium oxide that forms naturally on stainless steel. This film is what provides corrosion resistance.

Over time, or following manufacturing activities such as welding and machining, contaminants like free iron can become embedded on the surface. These weaken the oxide layer and make the material more reactive. Passivation removes these impurities and encourages the full development of a chromium-rich, inert film that resists oxidation and corrosion.

Modern passivation methods typically use citric acid blends or neutral oxidising solutions. These are safer and more environmentally responsible than older nitric acid or pickling techniques, and are particularly well-suited to industries where equipment surfaces come into contact with food, pharmaceuticals, or high-purity water.

For a detailed overview of how the stainless steel passivation process is applied in practice, including stages such as degreasing, derouging, and rinsing, see INOX’s technical guide.

Why Industries Depend on Passivation1. Compliance Across Sectors

- Pharmaceutical and Biotech:

Regulations such as EU GMP Annex 15 require equipment to be clean and fit for purpose. While passivation itself is not a legal requirement, it is a recognised method of maintaining stainless steel surfaces in a state that meets these standards. Rouge contamination, for instance, can lead to failed visual or swab inspections. - Food & Beverage:

Under Regulation (EC) No 1935/2004, food contact materials must not release substances that could endanger health or alter food composition. A passivated surface reduces the risk of corrosion, leaching, and microbial growth. Treatments that include derouging and biofilm removal are especially valuable in ensuring hygienic, inert equipment. - Energy and Utilities:

In power generation, petrochemicals, and water treatment, corrosion can lead to costly downtime or even safety hazards. Passivation helps maintain the reliability of cooling systems, pipelines, and process vessels. - General Manufacturing:

From automotive to electronics, stainless steel surfaces are critical to efficiency. Passivation ensures that machinery and components retain their corrosion resistance, preventing defects or early degradation.

2. Minimising Downtime

Unplanned downtime is among the most expensive risks in any industry. Emergency shutdowns to address corrosion, rouge, or contamination are disruptive and often more costly than routine maintenance.

By incorporating the stainless steel passivation process into scheduled maintenance cycles, organisations reduce the likelihood of last-minute interventions. The result: smoother operations, better resource planning, and fewer interruptions during audits or peak production periods.

3. Extending Asset Life

Corrosion is not just a cosmetic issue. Once stainless steel surfaces are compromised, the structural integrity of tanks, piping, and process systems is at risk. Passivation protects against this degradation, extending the lifespan of equipment and reducing long-term replacement costs.

This is particularly critical in sectors where assets are capital-intensive, such as pharmaceuticals, power generation, and large-scale food production.

4. Reducing Biofilm Formation

Biofilms—clusters of bacteria that adhere to surfaces—are a major challenge in industries working with water or organic materials. They are difficult to remove and can survive even aggressive cleaning.

Passivated stainless steel is smoother and less reactive, making it far less hospitable to biofilm formation. Combining passivation with derouging and biofilm removal creates surfaces that are easier to clean, more hygienic, and more resilient.

A Cross-Industry Scenario

Imagine three different facilities:

- A water loop in a biotech laboratory

- A mixing tank in a beverage plant

- A cooling line in a power station

Though operating in different contexts, all share the same vulnerability: corrosion of stainless steel surfaces. If untreated, this corrosion could lead to contamination, reduced efficiency, or outright equipment failure.

By implementing a routine passivation programme, each facility ensures its systems remain reliable, compliant, and ready for inspections. The process may look slightly different across industries, but the outcome is the same: improved resilience and peace of mind.

Key Standards and Best Practices

- ASTM A967 – Defines accepted methods for stainless steel passivation, including citric acid treatments widely used across industries.

- ASTM A380 – Provides guidance on cleaning and preparing stainless steel surfaces prior to passivation.

- ASME BPE – References passivation as a best practice for high-purity systems in life sciences.

- COSHH (UK) – Emphasises the safe handling of chemicals; citric and neutral oxidising blends align with modern safety and environmental expectations.

Conclusion

The passivation of stainless steel is not confined to one industry—it is a universal tool for protecting assets, ensuring compliance, and reducing operational risks. Stainless steel passivation strengthens surfaces against corrosion, minimises downtime, and supports the stringent hygiene or safety standards that industries face daily.

Whether in food production, pharmaceuticals, energy, or manufacturing, organisations that take a proactive approach to passivation will save time, reduce costs, and maintain confidence in their equipment.

For businesses seeking to integrate this into maintenance strategies, the stainless steel passivation process remains an indispensable part of sustaining long-term operational excellence.